Product Introduction

Quick Detail:

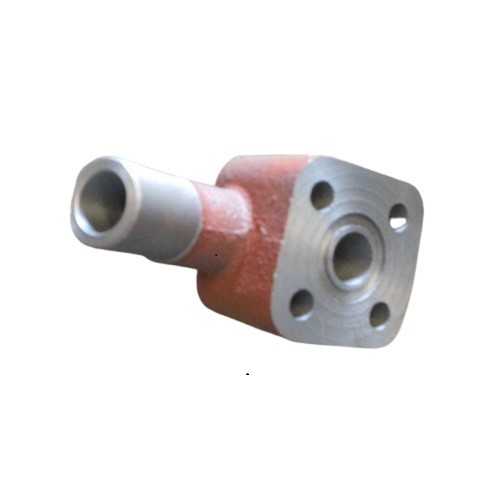

· ductile iron casting Oil

· ductile iron GGG40

· Sand Casting and CNC machining

· Shot Blasting and red painting

· Engine

| Ductile Iron Material Grade | ||||||||

| No. | China/GB 699 | Russia/ROCT | USA/ASTM A536 | England/BS | France/NF | Germany/DIN | Japan/JIS | ISO 683/1 |

| 1 | QT400-18 | BЧ40 | 60-40-18 | 400/17 | FGS370-17 | GGG40 | FCD400 | 400-18 |

| 2 | QT450-10 | BЧ45 | 65-45-12 | 420/12 | FGS400-12 | FCD450 | 450-10 | |

| 3 | QT500-7 | BЧ50 | 70-50-05 | 500/7 | FGS500-7 | GGG50 | FCD500 | 500-7 |

| 4 | QT600-3 | BЧ60 | 80-60-03 | 600/7 | FGS600-2 | GGG60 | FCD600 | 600-3 |

| 5 | QT700-2 | BЧ70 | 100-70-03 | 700/2 | FGS700-2 | GGG70 | FCD700 | 700-2 |

| 6 | QT800-2 | BЧ80 | 120-90-02 | 800/2 | FGS800-2 | GGG80 | FCD800 | 800-2 |

| 7 | QT900-2 | BЧ90 | 900/22 | 900-2 | ||||

Product Description:

Oil head of the main engine is a common name for the oil nozzle on the engine and other mechanical equipment. The oil head of the main engine is generally composed of a filter screen, a wire jack, an electromagnetic coil, a spring, an armature, a valve needle, and a valve seat. When the electromagnetic coil is energized, suction is generated, the needle valve is sucked up, the nozzle hole is opened, and the fuel is ejected at high speed through the annular gap between the needle of the needle valve head and the nozzle hole, forming mist gas, which generates energy through combustion. Thereby finally transforming into the kinetic energy of the main engine.

When changing the oil head of the main engine, it is often encountered that the oil head cannot be pulled out. The possible reasons are: the inside of the oil head hole on the cylinder head is not clean; the contact surface at the bottom of the oil head hole or the contact surface between the oil head and the cylinder head is concave The groove may be uneven, and heavy oil leaks into the oil head hole when the main engine is running. Usually, a special tool is used to pull out the oil head, but often because the oil head bites too tightly, the strength of the tightening bolt of the special tool is not enough, until the thread of the tightening bolt is damaged, the oil head cannot be pulled out;

Product Specifications:

| Commodity | Iron Casting & Machining Parts / Gear Cap |

| Standard | ASTM, DIN, JIS, EN, ISO, BS, JCSI, GB |

| Material | Grey iron (HT200,HT250,HT300), Ductile iron (QT400-18,QT400-15,QT450-10,QT500-7) |

| Unit Weight | 0,05 kg ~ 1,000 kg. |

| Tolerance | CT6-CT8 |

| Machining | Turning, Milling, Drilling, Cutting, Reaming, Threading, Welding, Tooling, etc |

| Surface Treatment | Shot blasting, Painting, Powder coating, Electroplating, Chrome plating, etc |

| Package | Standard wooden box package or as your customized package |

| Applications | Agricultural machinery, Petroleum machinery, Mining machines, Construction, Automotive & Truck, Medical, Marine, Railway & Train, Power lines, Furniture, Lighting, Flange, Valve and pump, Electronic, Pipeline, etc. |

| Brand | Twinkle Industrial |

Product Applications:

Widely used agricultural machinery, petroleum machinery, mining machines, construction, automotive & truck, medical, marine, railway & train, power lines, furniture, lighting, flange, valve and pump, electronic, pipeline, etc.

FAQ

Q1. How can we get a quotation?

A: Please send the parts 2D drawing (in PDF format) and 3D model in IGS or STP format together with material, production technique, purchasing qty, etc, or provide sample to us.

Q2. What about the lead time?

A: 15-20 days for Sample making ,20 working days for mass production.

Q3. Do you have any MOQ limit for casting parts?

A: It depends on different parts. For some parts, 1 pc can be acceptable.

Q4. What is your payment term?

A: Mold: 50% payment in advance, balance after the sample approval.

B: Mass production: 30% payment in advance, 70% balance before shipment.

Q5. What is your quality control process?

A: Each casting parts will be provided with raw material report ( chemical composition and physical property), and dimension measuring report before shipment.

Q6. How about the packaging?

A: Standard wooden box package or as your customized package.